User Tools

Sidebar

This is an old revision of the document!

Table of Contents

When things go wrong

Unlocking the stitch

Imagine I notice while sewing that the outcome is not as desired! The easiest way to undo what has been done is to raise the pressure foot and turn the hand wheel a full turn clockwise to unlock the last stitch. The needles will go down into the fabric and back up again and then the fabric can be pulled towards the left. The needle and looper threads can be pulled apart.

Removing the stitches

Alternatively, using the seam ripper, I can undo a few of the last stitches, gently pull the needle threads and the looper thread and bingo, I am ready to start over.

Needle thread looping on the wrong side

Skipped stitches

Maybe I should have started with this topic first since it seems to be a big concern among coverstitchers, often taking root even before a machine has been purchased.

OK, skips happen, that is a fact of coverstitch life. But there are simple ways of keeping this to a minimum.

Needles as I know them

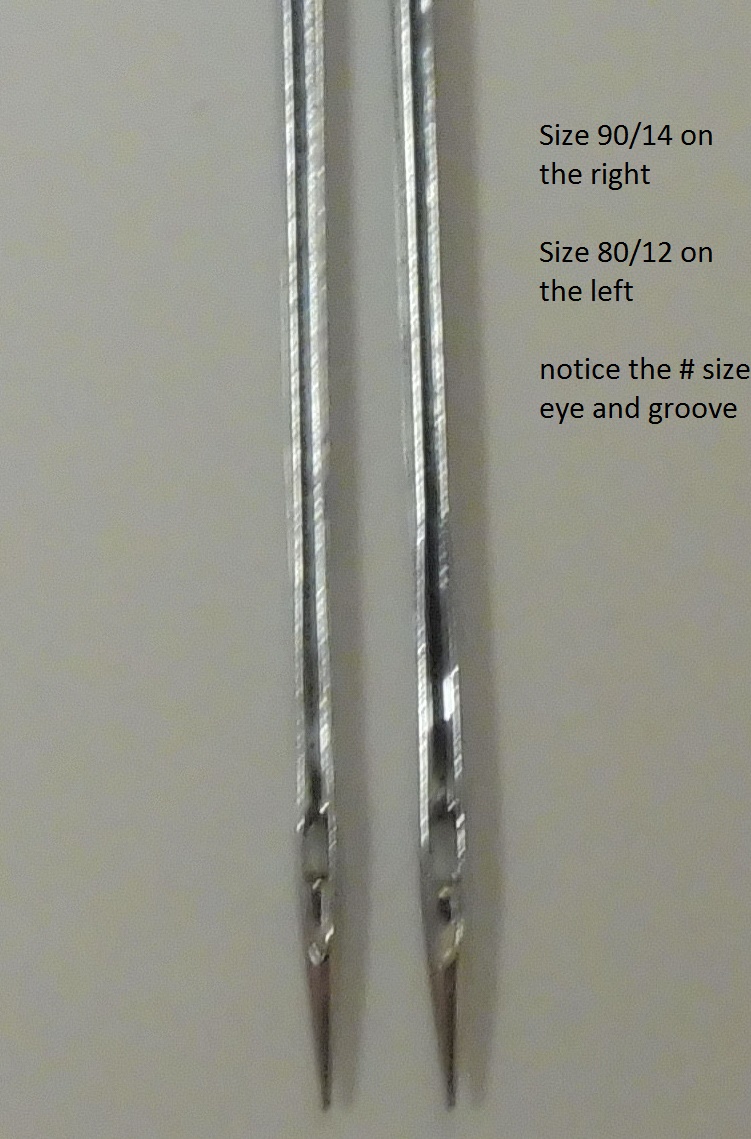

One cause of skipped stitches is using the wrong size needle. When coverstitching, the thread has to move back and forth through the eye of the needle and along the groove in the front part of the shaft. When the needle is the right size for the thread, fabric and the number of layers, the eye and the groove are both large and wide enough to enable the needle thread to move freely. Strategy number one for me is to check my needle size and most of the time I use a size 90/14. I have used this successfully for knits and woven fabric such as denim.

Please notice the difference in the size of the eye and the groove of the needles in the picture below, the one on the right hand is a size 90/14 and it has a larger eye and a wider groove.

Another reason for stitches skipping is the wrong needle type. Warning the following does not apply to certain brands of coverstitch machines, it applies to all those that use the ELX705 system. When sewing knits, especially those with a lycra content (trademark for a brand of spandex), I use ELX705 SUK needles. The SUK needle has a regular ball point which is best suited for knits. The ELX705 regular needle has a light ball point and is best suited for wovens.

When I run out of ELX705 SUK needles size 90, I use an ELX705 regular size 90 rather than an ELX705 SUK size 80. The right size is more important than the right type for avoiding skipped stitches in my opinion. I only switch to size 80/12 for very delicate fabrics, but if your experience differs, please do what works for you!

Move it, move it, move it.....

Another important cause of skipped stitches is stitches getting too short because the fabric is not feeding adequately. The stitches may get shorter as I sew over a hump or they may get shorter because there are an uneven number of layers or heavier fabric underneath the pressure foot.

Please notice the rick rack trim I attached with the coverstitch in the images below. Both examples were done on my Babylock Coverstitch machine. the top image shows the 2 needle narrow coverstitch going over rick rack trim. This did NOT work well, I had several skipped stitches. The reason I used my BLCS machine was that I had the right color thread in it and my sewing machine was threaded with adifferent color for other parts of the same project. i would normally not choose to use my coverstitch machine for this but I learned something valuable. Do you notice the stitches sometimes going through the rick rack and sometimes only going through the cotton fabric? That's where I got skips, the difference in number of layers caused the skip. My best guess is that with this constantly changing number of layers there is an irregularity in the feeding/needle penetration, much like left and right tyres going over different surfaces, and this difference may translate in a skipped stitch.

In the second sample I used the chain stitch and stitched 2 rows close to one another so that the needle was always penetrating the same number of layers and I didn't have a single skipped stitch. Something worth remembering.

Get to know the feed dogs

I have tested this only on a Babylock BLCS, a Janome 2000 CPX and a Pfaff 4874 so my experience does not cover other brands of machines and therefore the following may not correspond with your experience. On my Babylock simply increasing the diferential setting usually gets the fabric moving. On my Janome and my Pfaff machines I need to increase both the stitch length and the differential to enhance the feeding.

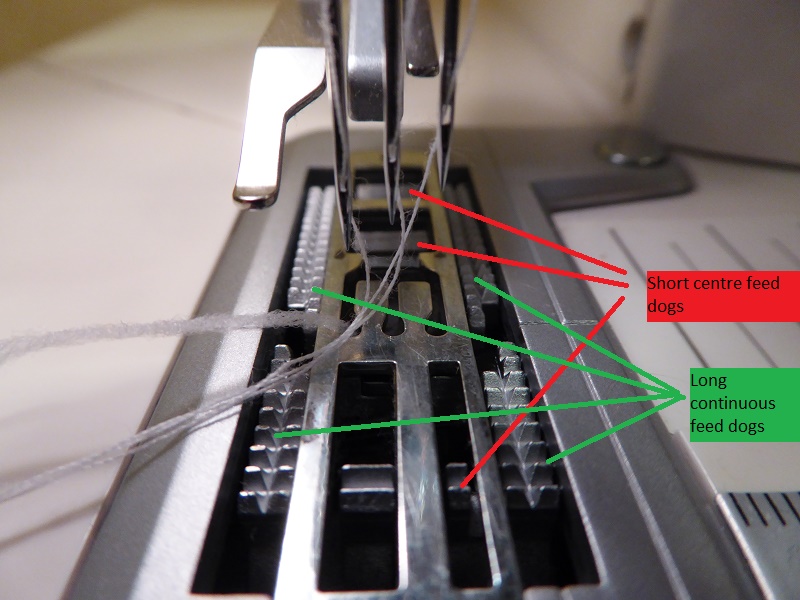

Even feeding is most likely to happen when the bulkiest part underneath the pressure foot is right there where the longer continuous feed dogs are. In the image below you can see that these longer feed dogs are on the left and right side. In the centre there are several short feed dogs but there is a large space where there id no feeding to allow for the needles to move up and down.

Now imagine topstitching a seam and the bulkiest part is in the centre. The longer feed dogs may get little or no hold of the fewer layers of fabric beside and feeding will not be even.

When I pick a differential setting that is suited for the fabric and application, the fabric should move evenly. When the number of layers changes, the feeding may slow down, resulting in the stitches getting shorter and eventually the looper thread not being connected properly to the needle threads. Another reason for poor feeding is the degree of stretch of the fabric. As the lycra content goes up, the fabric gets more and more elastic and this often results in short stitches, because between each movement of the feed dogs, the fabric has a chance to recover its natural with the looper thread skipping. Lycra knits vary between moderately to VERY stretchy and only the extremely stretchy ones are a challenge when coverstitching.

How come? I get less (a lot less) skipped stitches with my Babylock CS and in part I credit the Babylock feeding system for that. bunching up underneath th pressure foot. I notice that I do not have this problem with my Babylock, so I wanted to understand the difference because that might help me find a way to solve the skips on the Janome. The feed dogs are different. They differ in length, width and type (the Babylock seems to have more little points that grip the fabric). The major difference IMO is in how far the pressure foot extends BEYOND the feed dogs. The back edge of the Babylock pressure foot lands 1mm behind the feed dogs and the edge of the Janome pressure foot lands 4,5 mm behind the feed dogs. THAT is what can easlily cause the fabric to slow down or stop moving. One solution is to make the stitch longer because then the feed dogs make a larger movement and the risk of bunching up is reduced. In fact if you try this, you will probably notice less skips. But the disadvantage is that as the stitch gets longer it gets less stretchy, a hem f.ex. risks snagging and eventually the thread may break. My conclusion is that on the Janome VERY STRETCHY fabrics perform best with a stitch length around 3 and simultaneously supporting the movement at the back by gentle guiding the fabric away from the pressure foot while stretching in front of the pressure foot with the other hand. I stretch the fabric in front so that the maximum amount of thread goes into the stitch and once the fabric recovers, the stitch will look shorter and be very stretchy. Please note that for most lycra fabrics this is not necessary, I am talking about the very loosely knit and stretchy ones. Is that clear as mud?? smile emoticon

Needle threads looping on the wrong side

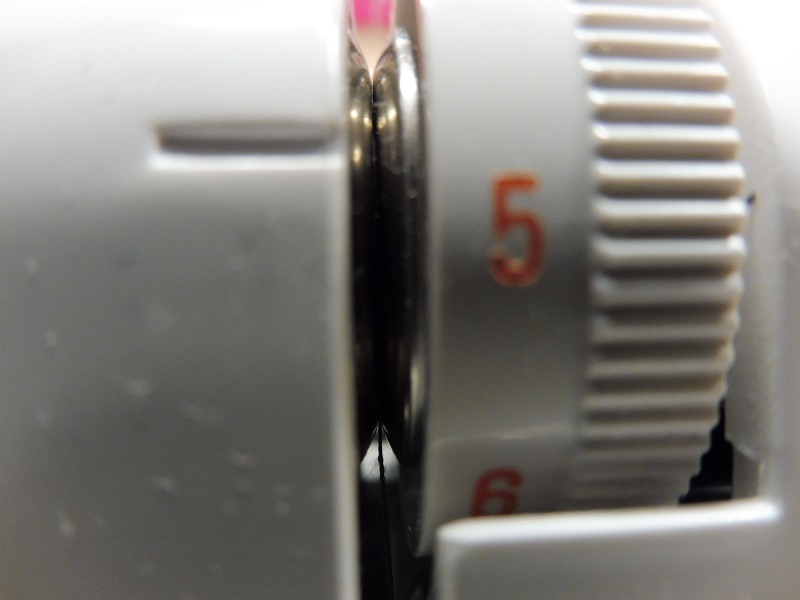

Ever come across this? It happens to me all the time. In this case I had been sewing a chain stitch with 1 needle and then I added a second needle but forgot to lift the pressure foot, so that the thread would slide between the tension discs.

This is what it looks like when the pressure foot is down and the thread is not engaged properly between the discs:

And this is what it should look like:

Which is why it is always a good idea to test on a scrap