Table of Contents

Top stitching

My never-ending topstitching story

A quick bit of history. I bought the first Janome Cover Pro model right after its introduction on the market. Hems and binding went mostly OK but top stitching and decorative reverse cover stitching didn't turn out the way I hoped. I then tried some other machines and eventually became very good friends or rather “attached” to my Babylock Coverstitch machine. Now many years later, I bought a Janome Cover Pro 2000 CPX, mostly because the Sewlock Holmes in me wanted to be sure she hadn't missed some 'user failure'. And having that large harp IS a bonus.

Top stitching and feed dogs

Several months and dozens of test patches later, my conclusion is that my Babylock BLCS is more stable when doing top stitching and reverse coverstitching than my Janome 2000 CPX. BUT I am determined to keep looking for ways to use my Janome for decorative stitching too. Here is what I have discovered so far:

For beautiful top stitching, I want those needle threads - or the looper in the case of reverse stitching - to be spaced evenly, no loops or tight spots or skipped stitches. Apart from testing the thread tension settings, I find that it is crucial to pay careful attention to the way the feed dogs move the fabric underneath the presser foot.

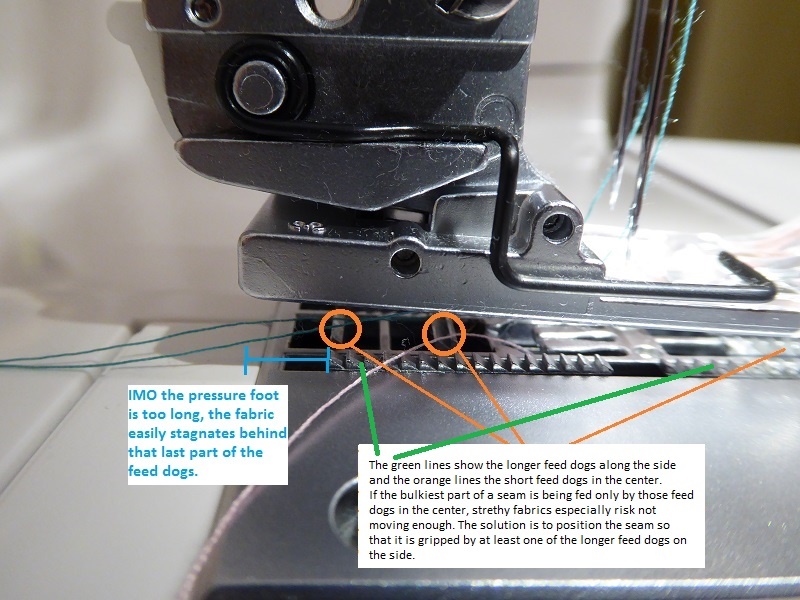

Here is a close up of the Janome 2000 CPX feed dogs.

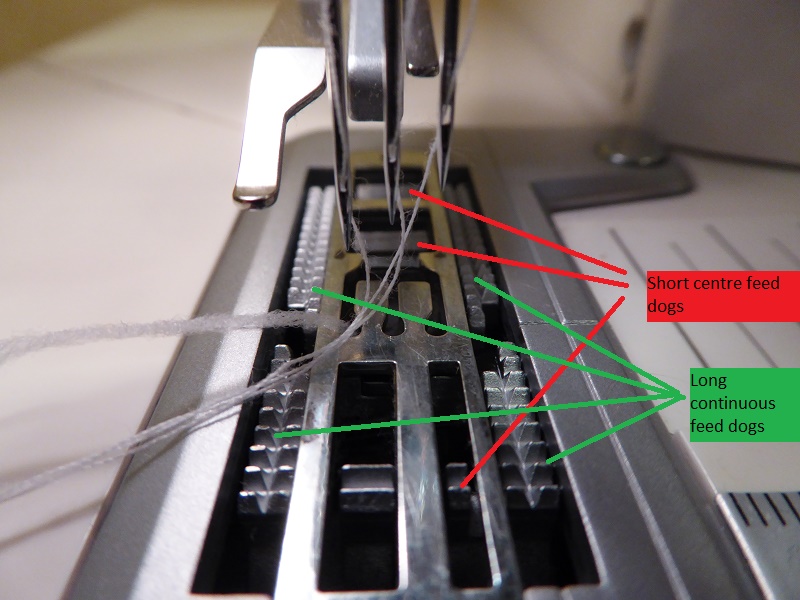

And here again a close up of the Babylock feed dogs. Please notice the longer continuous feed dogs along the sides and the short feed dogs in the center? There are some minor differences between the two brands but they seem to affect the feeding quite a lot. The Babylock presser foot is shorter and extending just a little beyond the feed dogs and the risk of fabric becoming stuck underneath the presser foot is reduced. The Babylock feed dogs are made differently, the metal seems to have plenty of tiny points which grip the fabric very effectively.

No matter which brand machine I use, this is how top stitching works best: the bulkiest part of the seam has to be gripped by the longer feed dogs, in this case the ones on the right. One can also work the other way around with the seam folded towards the left side.

The center guide foot may be very useful when top stitching because it will help to feed the fabric evenly and prevent it from sliding towards the center.

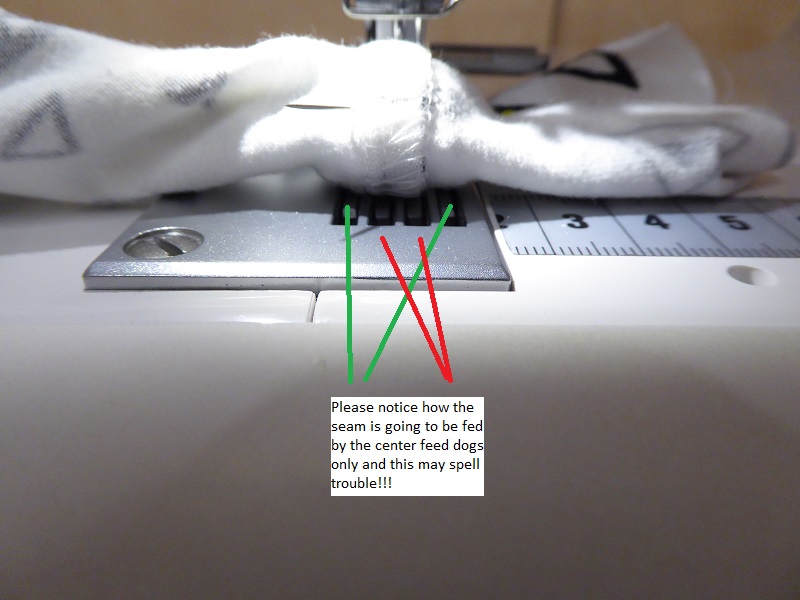

Let's say I think that I am fine with those stitches being further away from the seam line and I position the fabric as in the image below?

The seam is now positioned under the center of the presser foot and this risks the fabric not being fed evenly. The stretchier the fabric, the more it risks becoming stuck and stitches bunching up.

Pyjamas (or pajamas) with decorative reverse top stitching

It is difficult to give accurate tension or differential settings and stitch length that will fit every application. The following settings are what I used on my Babylock Coverstitch machine, when reverse top stitching 95/5 cotton lycra knit with average weight ribbing, using regular polyester sewing thread on paper core and cotton quilting thread on a mini cone in the looper. Tension settings may vary according to the weight of the thread, the weight and the number of layers of fabric to be pierced and even on the way the thread is wound. In this case I am using polyester sewing thread by Coats in needle 1 and 3 and a cheap polyester thread I got of eBay in needle 2. All threads are unwinding counter clockwise because for these threads it seems to minimize the risk of thread twisting and forming loops which may cause stitch irregularities or skipped stitches.

SETTINGS on the Babylock Coverstitch with this particular combination of threads and fabric:

Needle 1: 5

Needle 2: 5

Needle 3: 5.5

Looper 2.5

Stitch length 3

Differential 1.3

Please notice on the wrong side that I kept the right needle just a little to the right of the serger seam thread. That way the looper nicely covers the edge of the ribbed binding.